Welcome to Wood-Mizer

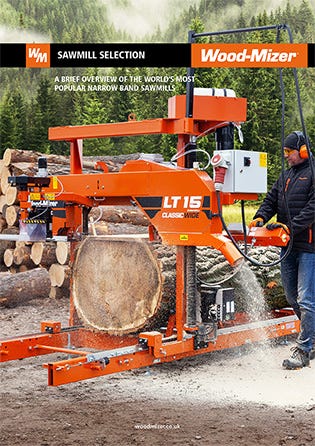

Partner with the world's most trusted sawmill and woodworking machinery brand to modernize your sawmill and grow.

The well-known and very popular LT40 sawmill has its new version in the form of the WIDE head with larger capacity.

Download our product catalogues or read stories from Wood-Mizer owners in one of our latest magazines!

CataloguesMagazines

Wood-Mizer CNC Routing Machines is a line of in house designed and produced, FANUC controlled processing centres.

100,000+ sawmill owners in 120 countries

100+ authorised dealers worldwide

40 Celebrating 40 Years of the Wood-Mizer Sawmill

15+ professional & industrial sawmills